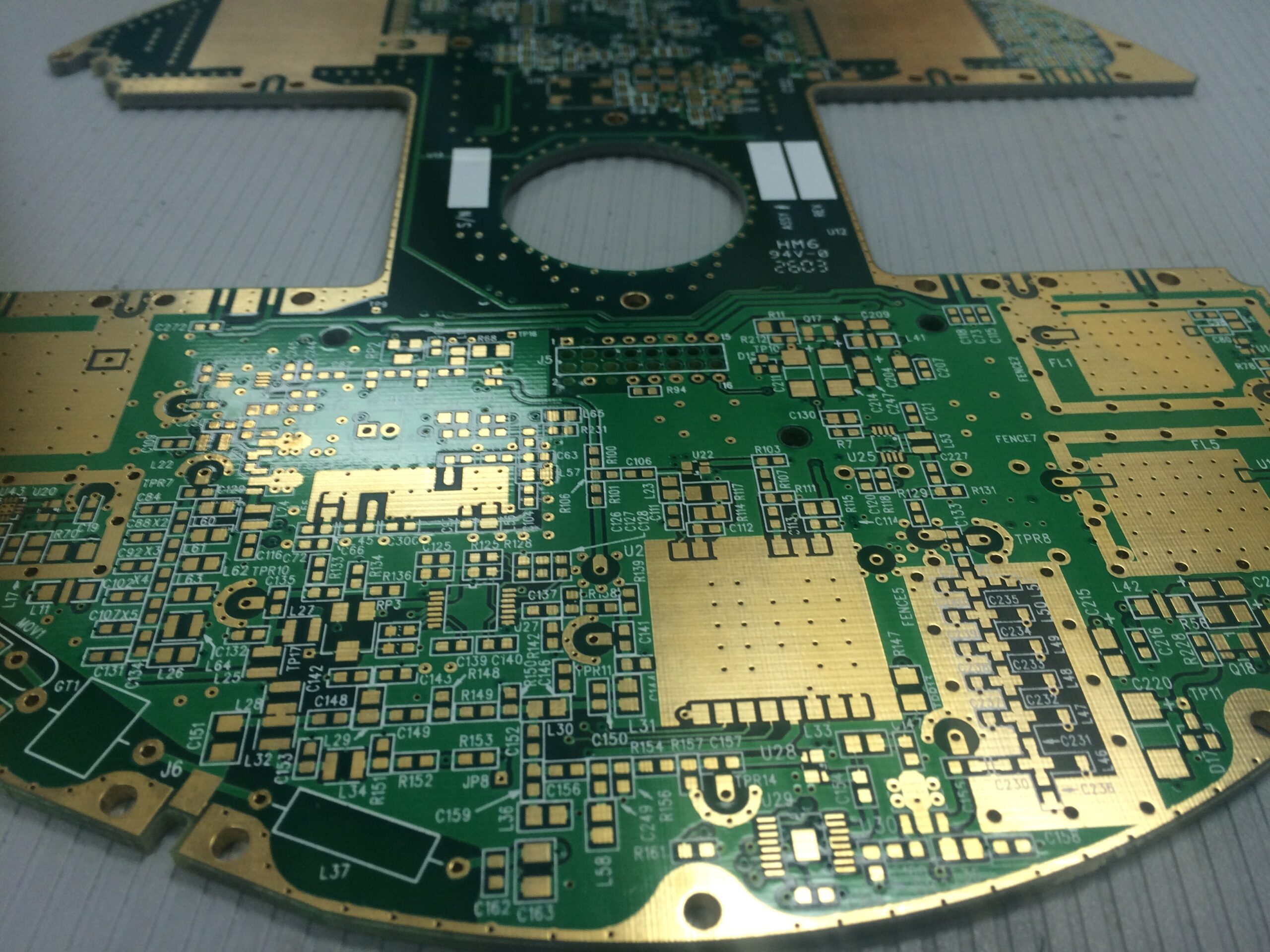

Flexible printed circuit boards (PCBs) have become a cornerstone of modern electronics, enabling compact, lightweight, and highly adaptable designs. They are widely used in industries such as medical technology, automotive electronics, aerospace systems, and consumer devices. Because these circuits must perform reliably under bending, vibration, and environmental stress, selecting the right production partner is one of the most important decisions you will make during product development.

Choosing a trusted Flexible PCB Manufacturer requires more than simply comparing prices. It involves carefully assessing technical capability, production quality, communication practices, and long-term reliability. This article provides a clear, professional guide to help you make an informed decision for your next flexible PCB project.

Start by Defining Your Technical Requirements

Before reaching out to suppliers, it is essential to have a full understanding of your project’s technical needs. This includes electrical performance, mechanical flexibility, environmental resistance, and physical constraints. The more detailed your specifications, the easier it will be to evaluate whether a manufacturing partner can truly meet your expectations.

Key elements to consider include board thickness, number of layers, copper weight, bend radius, dielectric material, and thermal performance. A well-prepared technical brief will save time and help avoid misunderstandings later in the project.

Assess Manufacturing Technology and Capabilities

Not all PCB manufacturers are equipped to handle the complexity of flexible circuits. You should investigate what equipment and processes potential partners use in their production lines. Advanced manufacturers typically invest in laser drilling, precision etching, automated lamination, and high-resolution inspection systems.

Industry knowledge and educational resources can also be valuable when evaluating manufacturing processes. For example, you can explore technical references and service overviews at https://www.pcb-togo.com/, which offers insight into modern PCB technologies and production standards.

A manufacturer with strong prototyping capabilities is especially valuable, as rapid iteration can dramatically speed up development timelines.

Review Certifications and Quality Control Processes

Quality control is critical in flexible PCB production. A reputable manufacturer should operate under internationally recognized quality management systems and adhere to established industry standards. These processes ensure consistency and reduce the risk of defects.

You should look for evidence of:

- Documented inspection procedures

• Material traceability systems

• Electrical and mechanical testing capabilities

• Continuous improvement programs

Strong quality systems translate directly into higher reliability and longer product lifecycles.

Consider Supply Chain Stability and Material Sourcing

Flexible PCBs rely on specialized materials that can significantly affect both performance and durability. A reliable manufacturing partner will be transparent about their material sources and provide clear information regarding availability and lead times.

Ask about their approach to inventory management, supplier relationships, and contingency planning. A stable supply chain reduces production delays and ensures consistent product quality throughout the life of your project.

Evaluate Communication and Engineering Support

Effective communication is often underestimated but plays a crucial role in project success. You should look for a manufacturer that provides clear timelines, responsive customer support, and direct access to engineering experts.

Engineering collaboration is particularly important for flex designs, as small layout changes can significantly impact manufacturability and performance. Strong partners provide design-for-manufacturability feedback and practical suggestions to improve performance and yield.

Look Beyond Initial Cost Estimates

While budget is always important, focusing only on the lowest quoted price can lead to poor outcomes. Low-cost providers may compromise on materials, testing, or process control, which can cause expensive failures later.

When comparing quotes, take into account tooling costs, setup fees, warranty policies, defect rates, and after-sales support. A higher upfront investment often results in lower long-term project costs.

Analyze Industry Experience and Proven Track Record

Manufacturers with experience across multiple industries tend to have more robust quality systems and stronger problem-solving capabilities. Reviewing past projects, certifications, and customer testimonials can give you valuable insight into their reliability.

Real-world case studies and sample products can help verify that a manufacturer can handle the technical complexity of your project and deliver consistent results.

Plan for Scalability and Long-Term Collaboration

A strong manufacturing partner should be able to support you not just during prototyping, but also when you move into full-scale production. Your chosen supplier should have the capacity, staffing, and infrastructure to grow alongside your business.

Reliable long-term partners can help streamline logistics, reduce costs over time, and support future product enhancements.

Final Thoughts

Selecting the right manufacturing partner directly impacts product performance, production efficiency, and long-term success. By carefully evaluating technical capability, quality standards, communication practices, and growth potential, you dramatically improve your chances of delivering a reliable, high-performing product.

For companies seeking a dependable and experienced provider, PCB-Togo Electronic.Inc offers comprehensive manufacturing solutions through. With professional support and modern production capabilities, the right partner can help transform even the most complex flexible PCB designs into successful, market-ready products.