Precision components are under greater surface stress than ever before. Higher speeds, tighter tolerances, and aggressive environments put pressure on metals that are already operating at the edge of their limits. Many engineers look for a surface method that reduces friction while maintaining weight, geometry, and material selection. This is why DLC coating continues to stand out in industries that rely on long-running, reliable parts.

What is DLC?

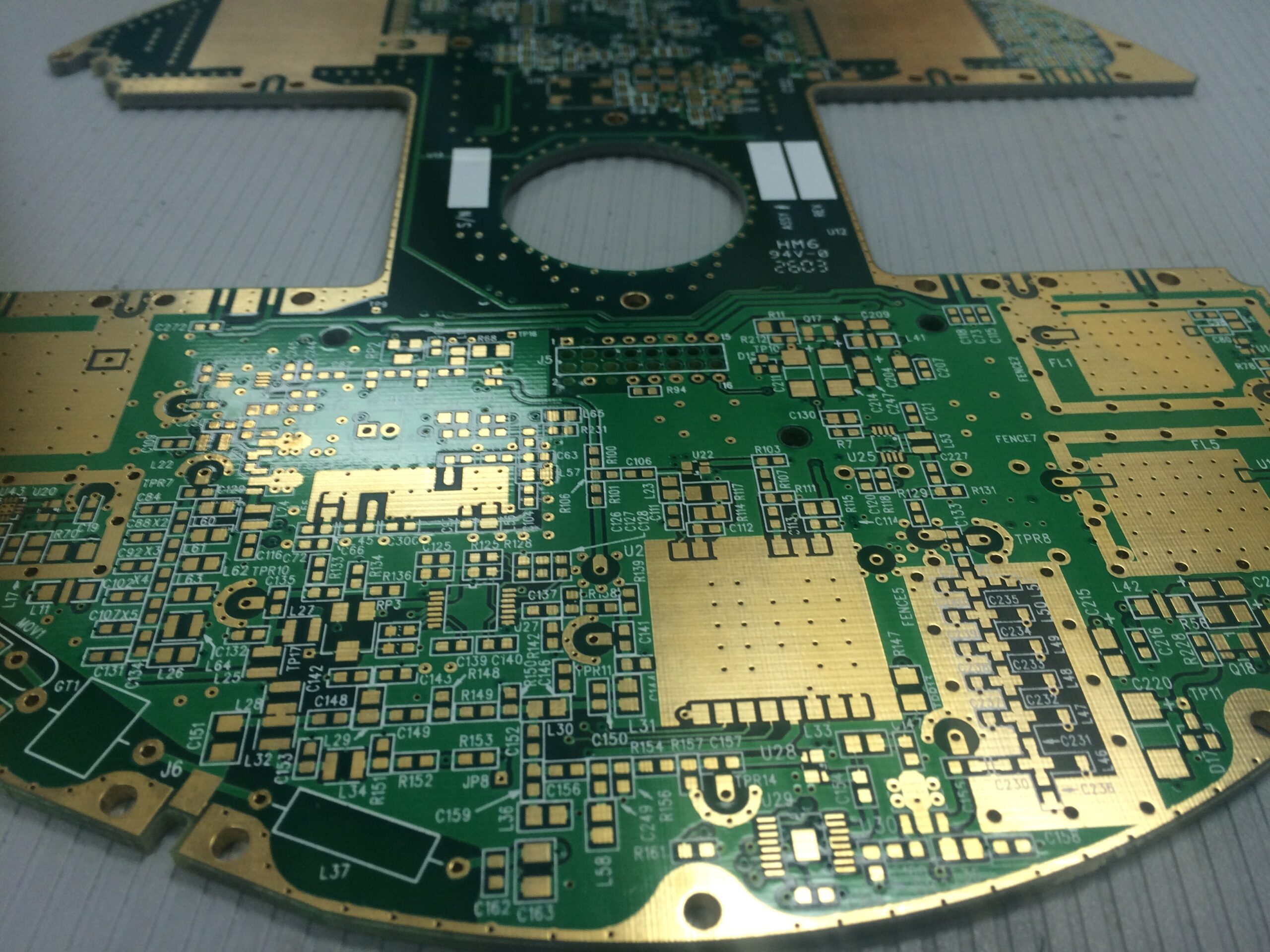

Diamond-like carbon (DLC) films play a central role in modern surface engineering. They combine hardness, smoothness, and chemical stability into a single thin layer. These qualities help parts survive repeated sliding, rotating, and impact events. Engineers use DLC on cutting tools, automotive parts, aerospace components, firearms, medical devices, and other precision assemblies that encounter friction or abrasive contact daily.

Lower Friction In High-Speed Motion

Friction drives heat, vibration, and wear. These issues show up quickly in parts that operate at high speed. Cutting inserts lose their sharp edges. Engine components heat up during long cycles. Small firearm parts drag against each other during rapid movement. Each problem ties back to surface friction.

DLC’s structure reduces drag between metal and other surfaces. The smoothness of the coating helps the part glide rather than scrape. This reduction in drag reduces heat buildup, directly improving stability in long-running systems. A piston pin, for example, can handle long cycles without rapid surface deterioration. A cam follower runs cooler and keeps its shape during constant contact.

The reduction in friction also supports accuracy. Cutting tools retain their geometry longer, helping maintain clean cuts. Moving parts run with fewer heat spikes, keeping tolerances tighter over long operation.

Wear Resistance In Harsh Contact Conditions

Wear grows from repeated surface contact. Even polished metal contains tiny peaks. These peaks rub against each other under pressure and break off. Once this begins, the surface roughens. A rough surface traps debris, accelerating wear.

DLC protects against this by serving as a hard, abrasion-resistant layer. The film takes the contact instead of the base metal. This slows the loss of material and keeps the part stable for longer periods.

Many industries see this benefit in heavy daily use:

- Cutting tools retain sharp edges during aggressive cuts.

- Automotive parts withstand long cycles without scuffing.

- Aerospace pins and actuators handle sliding contact with fewer surface changes.

- Medical components face repeated sterilization and contact without easily losing surface integrity.

The film also resists chemical wear. Some metals degrade when exposed to fuel, oils, or cleaning agents. DLC keeps these agents away from the base material, which protects its long-term performance.

Stability Under High-Speed And High-Load Operation

High-speed assemblies create rapid changes in pressure and temperature. These changes stress the surface and force the metal to respond. Many metals soften when heated or lose strength under repeated cycles.

DLC remains stable under fast movement and frequent load changes. The film protects the substrate from direct heat exposure. It also reduces material transfer between contacting surfaces, which helps prevent adhesion damage.

High-quality DLC coating service supports heavy mechanical loads by spreading stress across the surface. This protects the base material from deformation at contact points.

Choosing The Right Coating Partner

Selecting a surface method is one step. Making sure the process supports the part’s long-term performance is another. Engineers look for consistent thickness, strong adhesion, and a clean, controlled deposition environment. These factors decide how well the film bonds to the substrate.

The best results come from providers who understand substrate preparation, heating limits, and the performance targets of the final part. DLC responds well to clean surfaces and reliable bonding layers. When the application demands repeatable performance, these process details matter.

Conclusion

DLC stands out because it supports real performance demands. Low friction, strong wear resistance, and stable high-speed performance make it an ideal fit for precision components. A high-quality DLC coating helps parts stay sharp, smooth, and reliable through extended cycles. Working with a skilled DLC coating service enhances these advantages by providing the film with the adhesion and consistency needed for demanding environments. As assemblies run faster and hotter, DLC continues to provide engineers with a reliable way to control surface stress and extend part life.