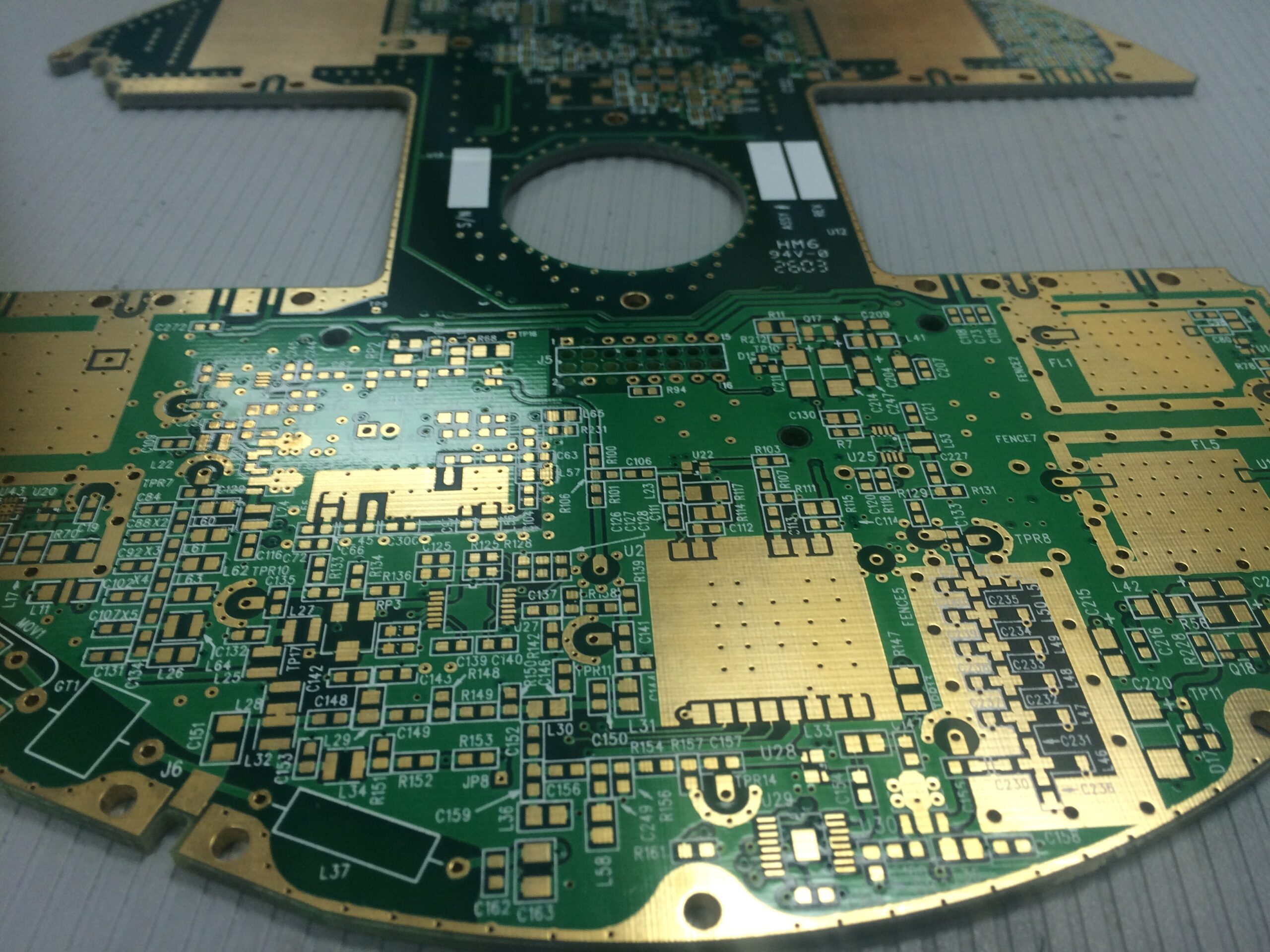

Gear shaper cutters have been massively used for varied purposes, such as cutting internal gears. These are also an effective way for adding the sprockets to enable the complex tooth profiles. These gears will be the best way to save more money in the process. Reliable are also assured of bringing premium quality tools that are suitable for the machining process. These are also suitable options for generating gear tooth profiles in varied materials. These gear shaper cutters cannot be cut by hobbing. These are known for their durability to withstand high friction and heat.

Versatility:

Gear shaper cutters are suitable for both specialized as well as mass production. The Gear shaper cutters can cut both internal and external gears. It is the best option for cutting the splines that are difficult or even impossible to produce using other methods. In the modern day, the gear shaper cutters are a widely used cutting tool for processing gears. Gear shaper cutters have been widely used in the gear manufacturing process and are suitable for saving more time.

The gear shaper cutters are widely used for precision cylindrical gears for various applications. This gear will be machined with the gear shaper cutters for adding more thickness to the gear body around the bore. The central bore will be broached, allowing the spur gear to fit in the keyed shaft or spline.

Accuracy:

The gear shaper cutters produce high precision with dimensionally perfect gears. These can be easily optimized for specific applications. The configuration of external gear from the is enabled with the gear shaper cutters having teeth on the cylinder’s surface. These would mesh with another gear, allowing the gear to rotate in its opposite directions.

The Internal Gear has teeth cut on its inner surfaces. Inner Gear teeth mesh has the smaller gear or pinion. Gears rotate in similar directions. The gears are used in mechanical applications to increase the speed of the machine. Gear shaper cutters have simple designs without any complicated form, so it is easier to manufacture and compact to install.

Transmission Efficiency:

gear shaper cutters especially have higher transmission efficiency, making them ideal for adding more efficiency. These gears are reliable and durable, having fewer opportunities for failure. Gear shaper cutters provide a constant velocity ratio; it is ideal for applications. The manufacturing process of gear shaper cutters begins with the gear blanks, as well as many other components. The quality of gear depends on the type of materials used. High-quality gears made from high-quality materials, so they will be suitable for achieving better efficiency.

Cutting Complex Designs:

The gear shaper cutters can precisely create gears with custom tooth profiles. These are enabled with the involute curves, as well as, suitable for specialized requirements such as shoulder gears. It is quite a convenient option for producing all types of gears, even beyond the gears. The manufacturing process involves a machine to produce the cutter passing gear blank.